Blog

How Industrial Maintenance Impacts Operational Efficiency and Safety

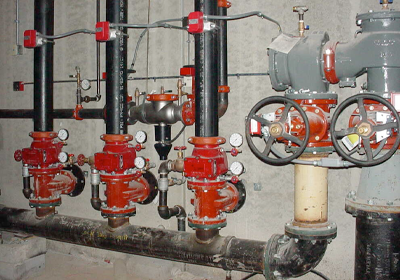

In industrial facilities, maintaining smooth and safe operations is paramount. Whether managing manufacturing equipment, HVAC systems, or critical infrastructure, industrial maintenance plays a vital role in optimizing operational efficiency and ensuring a safe working environment. Regular, proactive maintenance not only prevents costly downtime but also safeguards employees by addressing potential hazards before they escalate.

In this article, we’ll explore the various ways industrial maintenance impacts operational efficiency and safety and why it’s crucial for businesses to prioritize these services in their day-to-day operations.

1. Minimizes Equipment Downtime

Unexpected equipment failure can bring operations to a halt, costing both time and money. Regular industrial maintenance reduces the likelihood of unplanned downtime by ensuring that all machinery and equipment are in optimal working condition. Routine inspections, cleaning, and adjustments help identify minor issues before they become serious problems, allowing repairs or replacements to be scheduled at convenient times.

By keeping equipment running smoothly, industrial maintenance improves production flow and reduces the risk of interruptions, enabling companies to meet their deadlines and maintain a consistent output.

Want to minimize downtime? Contact Baker Mechanical Systems to develop a customized maintenance plan.

2. Extends Equipment Lifespan

Industrial equipment is a significant investment, and extending its lifespan through maintenance can save companies substantial costs over time. Without regular maintenance, parts wear down more quickly, leading to increased breakdowns and the need for expensive replacements. Well-maintained equipment operates more efficiently, generating less stress on components and reducing wear and tear.

A proactive maintenance approach helps ensure that equipment runs efficiently for its intended lifespan, maximizing return on investment and reducing the frequency of costly replacements.

3. Increases Energy Efficiency

Regular maintenance doesn’t just keep equipment functioning—it also optimizes performance, which can improve energy efficiency. Machines that are clogged with dust, debris, or have worn-out parts often consume more energy to operate. By maintaining components like motors, fans, and HVAC systems, facilities can reduce energy waste and cut down on utility expenses.

In today’s environmentally conscious business climate, improving energy efficiency also supports sustainability goals, reducing the carbon footprint of industrial facilities.

Looking to improve energy efficiency? Schedule a maintenance consultation with Baker Mechanical Systems for tailored solutions.

4. Enhances Safety for Employees

Industrial facilities often operate with heavy machinery, electrical systems, and other equipment that can pose safety hazards if not properly maintained. Regular maintenance includes inspecting for potential safety risks, such as loose parts, electrical issues, or malfunctioning equipment. Addressing these hazards before they lead to accidents creates a safer work environment, reducing the risk of injuries and promoting employee well-being.

For companies, a focus on maintenance-driven safety also supports compliance with Occupational Safety and Health Administration (OSHA) standards and other regulatory requirements, which can help avoid penalties and legal issues.

5. Improves Quality Control

When equipment operates efficiently, product quality improves. Worn-out components or inconsistent machinery performance can lead to defects, affecting the quality and reliability of products. Regular maintenance ensures that machinery is calibrated, lubricated, and functioning as intended, resulting in consistent product quality.

For industries where precision and consistency are essential, such as food processing, pharmaceuticals, and automotive manufacturing, maintaining high-quality standards through regular equipment maintenance is critical.

Keep quality control at the forefront—reach out to Baker Mechanical Systems for a comprehensive maintenance strategy.

6. Enables Predictive Maintenance Strategies

With advances in technology, predictive maintenance has become a valuable tool in industrial facilities. Predictive maintenance uses data from sensors and monitoring systems to identify early signs of wear or failure, allowing maintenance teams to address issues before they cause breakdowns. By implementing predictive maintenance, companies can minimize downtime, reduce repair costs, and make data-driven decisions to optimize asset performance.

Modern maintenance approaches combine predictive and preventative strategies, creating a balanced approach that ensures efficiency and reliability.

7. Lowers Long-Term Maintenance Costs

Though maintenance requires an upfront investment, it significantly reduces long-term costs by preventing major breakdowns and extending equipment life. Catching small issues early through regular inspections costs much less than dealing with emergency repairs or full equipment replacements. By prioritizing proactive maintenance, facilities can allocate resources more efficiently and avoid unexpected expenses.

Want to lower long-term maintenance costs? Connect with Baker Mechanical Systems to discuss cost-effective maintenance solutions for your facility.

8. Ensures Regulatory Compliance

Industrial facilities are often subject to strict regulations that govern everything from environmental standards to worker safety. Regular maintenance is essential for ensuring compliance with these regulations. By adhering to maintenance schedules and keeping records, facilities can demonstrate compliance during audits and inspections, avoiding potential fines or shutdowns.

Staying compliant not only protects the facility legally but also enhances its reputation as a responsible, safety-conscious business.

9. Supports Business Continuity

In today’s competitive market, companies can’t afford frequent disruptions to their operations. An effective maintenance strategy is essential for supporting business continuity, helping facilities avoid shutdowns that could affect production schedules and customer relationships. Consistent operations not only protect revenue but also build trust with clients and stakeholders who rely on timely delivery of products or services.

Secure business continuity with a robust maintenance plan from Baker Mechanical Systems.

Enhancing Operational Efficiency and Safety Through Industrial Maintenance

Regular industrial maintenance is crucial for optimizing efficiency, improving safety, and reducing costs in commercial and industrial facilities. By investing in proactive maintenance strategies, companies can keep their equipment running smoothly, improve quality control, ensure regulatory compliance, and create a safer work environment.

If you’re looking to enhance operational efficiency and safety in your facility, consider working with Baker Mechanical Systems in Rochester, NY. With customized maintenance plans, predictive maintenance solutions, and a team dedicated to excellence, we’ll help you keep your facility operating at its best.

Ready to boost efficiency and safety? Contact Baker Mechanical Systems today to discuss a tailored industrial maintenance plan.

‹ Back