Blog

Why Regular Maintenance Extends the Life of Industrial Process Piping

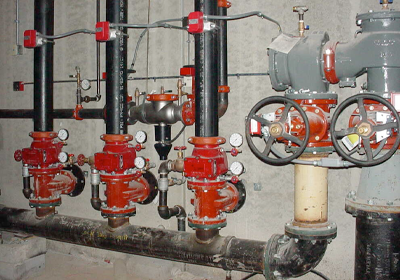

Industrial process piping systems are the backbone of many commercial and industrial operations, transporting liquids, gases, and chemicals essential to production processes. Given their critical role, keeping these systems in good condition is essential for smooth operations, safety, and long-term cost savings. Regular maintenance is the key to ensuring the longevity and reliability of your industrial piping system.

In this article, we’ll explore why regular maintenance is so crucial for extending the life of industrial process piping and how proactive care can prevent costly breakdowns, minimize downtime, and keep your operations running efficiently.

1. Prevents Corrosion and Material Degradation

One of the biggest threats to the lifespan of industrial process piping is corrosion. Exposure to chemicals, moisture, and various environmental factors can cause the materials to degrade over time, leading to weakened pipes, leaks, and potential system failures.

Regular maintenance allows for early detection of corrosion and the application of preventative measures such as protective coatings, pipe replacements, or chemical treatments to slow down the degradation process. Identifying and addressing these issues before they become severe can extend the lifespan of your piping system by years.

Ensure your piping system is protected against corrosion—schedule a maintenance check today.

2. Detects Leaks Early

Small leaks in industrial process piping may seem minor at first, but they can quickly turn into bigger problems if left unchecked. Leaks not only lead to wasted resources but can also cause equipment damage, reduce system efficiency, and pose safety hazards.

Regular maintenance allows for the early detection of leaks before they escalate into more serious issues. By inspecting joints, valves, and connections regularly, your team can catch leaks early and perform the necessary repairs to prevent further damage to the system.

3. Reduces the Risk of Unexpected Downtime

Unplanned downtime due to process piping failure can have a significant financial impact on industrial operations. When piping systems are not regularly maintained, they are more prone to sudden breakdowns, which can bring production to a halt. The cost of lost productivity, emergency repairs, and potential equipment replacement can be substantial.

Routine maintenance helps to identify potential problems before they cause system failure, reducing the risk of unexpected downtime. By scheduling regular inspections and performing preventative repairs, you can ensure your process piping system remains reliable and operational throughout the year.

Avoid costly downtime with proactive maintenance. Contact us today to schedule service.

4. Improves Safety and Reduces Hazards

In many industrial settings, process piping systems carry hazardous materials, including chemicals, gases, and high-temperature fluids. Any failure in these systems can create serious safety hazards for workers and the surrounding environment. Leaks, ruptures, or bursts can result in exposure to dangerous substances, fires, or explosions.

Regular maintenance helps ensure that all components of your industrial process piping system are in safe working condition. Inspections can identify weakened areas, pressure imbalances, or other risks that could lead to dangerous situations. By staying ahead of these issues, you can maintain a safe working environment and reduce the likelihood of accidents or injuries.

5. Increases System Efficiency

Efficiency is key in any industrial operation, and an aging or poorly maintained piping system can significantly reduce overall productivity. Clogs, buildup, or internal damage in the pipes can obstruct flow, leading to reduced efficiency and higher energy consumption.

Regular maintenance, such as cleaning and flushing the piping system, can help remove any buildup or blockages that may be slowing down operations. Ensuring that all components are functioning optimally can lead to more efficient system performance, saving energy and improving production rates over time.

Maximize the efficiency of your process piping system with regular maintenance—schedule an inspection now.

6. Extends the Life of Critical Components

Industrial process piping systems are made up of numerous components, including valves, pumps, joints, and fittings. These components experience wear and tear over time and can become weak points in the system if not properly maintained.

Regular maintenance includes inspecting and servicing these critical components to ensure they are in good working condition. Replacing worn-out parts or addressing small issues early can prevent larger, more expensive repairs in the future and extend the overall life of your piping system.

7. Compliance with Industry Regulations

Many industries are subject to strict safety and operational regulations regarding their piping systems. Failing to properly maintain these systems can result in non-compliance, leading to penalties, fines, or operational shutdowns.

Regular maintenance ensures that your industrial process piping system is in compliance with all relevant industry standards and regulations. By keeping accurate maintenance records and performing the necessary inspections, you can avoid legal trouble and keep your operations running smoothly.

8. Lowers Long-Term Repair Costs

One of the most significant advantages of regular maintenance is the long-term cost savings it provides. While it may seem costly to schedule routine maintenance, the expenses associated with emergency repairs, system replacements, and downtime can be far greater.

By investing in regular maintenance, you can address minor issues before they become major problems, avoiding costly repairs and extending the life of your process piping system. Preventative care is always more cost-effective than reacting to system failures after they occur.

Save money in the long run with regular process piping maintenance—request service today.

Rochester, NY Industrial Process Piping

Regular maintenance is critical to extending the life of your industrial process piping system and ensuring the smooth operation of your facility. From preventing corrosion and leaks to improving safety and efficiency, proactive maintenance helps avoid costly repairs and unexpected downtime. By keeping your system in top condition, you can save time, money, and ensure compliance with industry regulations.

If your industrial process piping system is due for maintenance, don’t wait—contact Baker Mechanical Systems today to schedule an inspection and keep your operations running efficiently.

‹ Back